- Hypermill file to solidworks serial#

- Hypermill file to solidworks software#

- Hypermill file to solidworks download#

Hypermill file to solidworks software#

Acknowledged as the industry leading manufacturing software package in the high-end aerospace and F1 sectors, hyperMILL seamlessly enables us to get parts to market with greater speed and precision than our rivals.Ĭapable of working with all file formats such as IGES, STEP, CADL, DXF, ASCII, NCAL, PAR, PRT, SAT, SUP, STL, Solidworks, Catia, WorkNC and much more, hyperMILL enables us to rapidly transfer your drawing or file into a high quality machined component at blistering speeds. This is why our production department operates the hyperMILL CAD/CAM software from OPEN MIND Technologies.

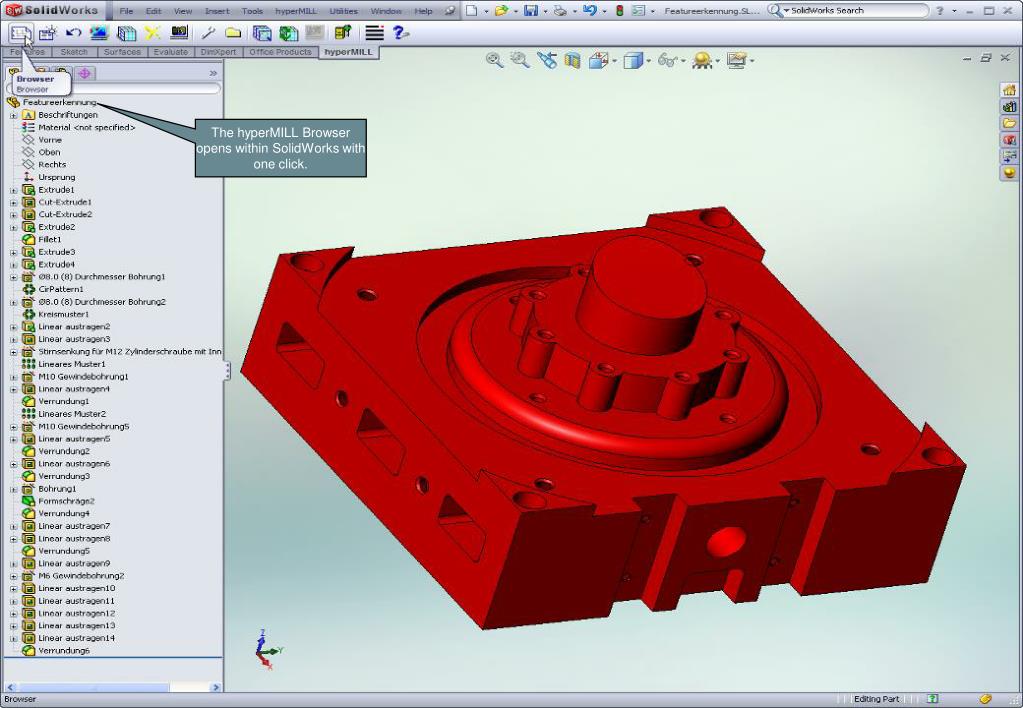

With new workspace monitoring the user can check in advance whether the machining job can be performed within the given workspace or whether limit switches will be crossed. The postprocessors, tailored to specific machines, controllers and manufacturing processes, ensure that the CAM programs are processed seamlessly on the machine. Programming efforts are reduced with sophisticated feature technology, including feature recognition, automatic mapping of hole and pocket features, feature list, feature browser, macro technology and macro database. an array of strategies for 2D, 3D, HSC and 5-axis machining, as well as MILLING and TURNING, in one user interface.The standard user interface from the CAD environment simplifies CAM programming and raises the user’s acceptance of the CAM solution. A uniform data model is used during the entire process in order to ensure the accuracy and transparency of the manufacturing process and to prevent errors. The CAD and CAM systems both access the same pool of data. The advantage provided by the CAM-integrated in the CAD solutions is that they enable the realisation of continuous process chains.

Complete integration into the core of the host CAD system SOLIDWORKS ®.Programme 3D-CAM for the automatic programming of CNC machines (milling machines, machining centres, lathes) with: The following chart shows how our CAM programming system is organised and interfaced/connected to the CNC machine tools:

Hypermill file to solidworks download#

This connection allows programme download and storage after processing to ensure repeatability on future batches.ĪGAZZI GIANCARLO srl creates CNC programmes using the HYPERMILL® e HYPERTURN® - OPEN MIND.

Hypermill file to solidworks serial#

AGAZZI GIANCARLO srl carries out all types of MILLING and TURNING operations regardless of their complexity through suitable CAD-CAM software products that use post-processor programmes to generate CNC lists for the machine tools deployed at our company.Īpplying the processing technology to a profile/surface can be done directly within the CAM programme by creating a model out of a paper drawing or using IGES/STEP format files or native files made by other CAD systems ( Inventor ®, Catia ®, Pro-Engineer ® ) that have either been made by our technical office or provided by the customer.Īll of the CNC machines deployed within our company are interfaced with the CAM programme through a serial network connection managed by a data transfer management software.

0 kommentar(er)

0 kommentar(er)